Innovation from the Leader in Nanocoating

With more than 25 years of experience in Low Pressure plasma engineering and applications, Europlasma is the world’s leader in Plasma Enhanced Chemical Vapour Deposition (PECVD) conformal coatings for electronics.

Europlasma employs some of the world’s foremost experts on PECVD and has been known for its commitment to innovation and continuous improvement.

Years of Research has led us to a major breakthrough in a coating that is not only an extremely strong barrier, but is entirely free from any halogens. Having all the benefits of our previous nanocoatings and surpassing them in many ways PlasmaGuard E has among the other the following benefits:

Europlasma employs some of the world’s foremost experts on PECVD and has been known for its commitment to innovation and continuous improvement.

Years of Research has led us to a major breakthrough in a coating that is not only an extremely strong barrier, but is entirely free from any halogens. Having all the benefits of our previous nanocoatings and surpassing them in many ways PlasmaGuard E has among the other the following benefits:

- Excellent Dielectric properties

- Highly hydrophobic (Water contact angle 120°+)

- Unparalleled chemical and moisture barrier properties

- Fully Biocompatible

- Ultra-thin, really conformal coating

- Pinhole Free

- Excellent crevice penetration

- RoHS and REACH compliant

- Very environmentally friendly and sustainable coating.

- Plasma Guard E complies with European Union’s RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) directives. PlasmaGuard E is also completely free of any VOC, Lead or other metals and crucially any halogen content.

- The halogens elements are fluorine (F), chlorine (Cl), bromine (Br), iodine (I), astatine (At), and tennessine (Ts). Many conformal coatings including parylene contain these hazardous chemicals in some form.

- Globally there is a drive towards the elimination of halogens in electronics and Europlasma has now made this a little easier with Plasma Guard E.

- PlasmaGuard E is Biocompatible according to ISO 10993-5 and Not hypersensitive according to ISO 10993-10

Plasma Guard E Coating properties. Testing the barrier strength.

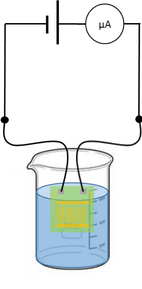

•To test the barrier properties we compare Plasma Guard E with Parylene, generally considered the best barrier coating material. For this comparison we use a short cut test in water, artificial sweat and salt water.

•This test consists of a submersion of a SIR board with an ENIG surface finish and applying 5V once submerged. The current that flows from the legs of one fork to the legs of the other fork is then measured. When the resistance drops because of short circuiting and failure, the current increases. We consider a current of 0.1 mA

• At the same thickness Plasma Guard E outperforms Parylene in every type of liquid. And even when Parylene is applied at 5x the thickness it is still being outperformed by PlasmaGuard E.

To receive the full test results, contact us.